Before buying stirred tank, read this guide.

它擁有所有信息,可幫助您選擇高性能和優質攪拌罐。

讓我們潛入。

What is a Stirrer Tank?

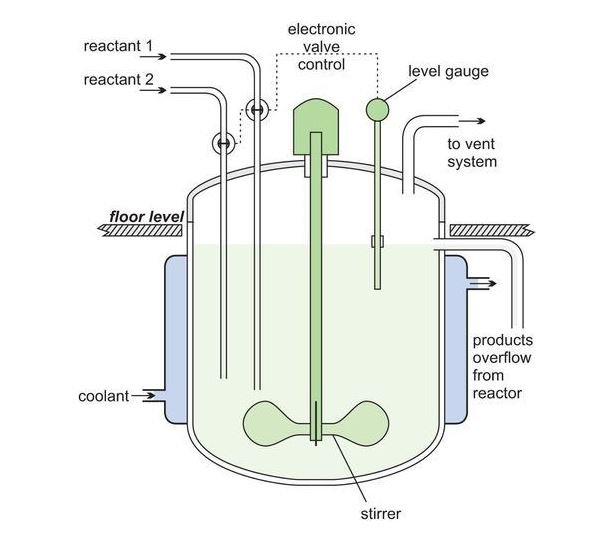

Stirred tanks are special types of units that you can use in the process of mixing different chemical ingredients.

您將在化學工程中使用它來混合不同類型的化學試劑,連續攪拌它們以完美。

攪拌罐

Which Types of Compounds Can You Mix Using the Stirred Tank?

You can mix different types of compounds using the stirred tank depending on the mode of application.

以下是您可以在攪拌罐內舒適地混合的一些化合物。

- Chemical Compounds

- Biological Compounds

You should note that the above compounds can be in the form of liquids, solutes or solution thus forming complete mixtures.

什麼是攪拌罐中的停留時間分布?

每種化學物質或生物化合物都會在攪拌器罐內花費大量時間。

You should note that the amount of time every compound will spend within stirred tanks vary depending on the compound.

停留時間分布是離散量的化學化合物將在攪拌罐中花費的時間。

攪拌罐內的停留時間分布將取決於反應器體積以及流體流速。

哪些行業使用攪拌罐?

Stirred tank

You can use the stirred tank in different applications to mix different types of compounds.

以下是兩個主要應用,需要攪拌器罐的服務。

·環境工程應用

您將使用環境工程行業中的攪拌罐來執行以下功能,如:

- Water treatment through the process of activated sludge

- Waste water treatment through the lagoon treatment systems.

- 通過使用厭氧消化器廢水生物多體穩定

·化工工業

您將使用化學工程行業中的攪拌罐進行不同的功能,如:

- 使用環路反應器的藥物生產

- 不同化學化合物的發酵過程

- Production of biogas by mixing different type of biogas producing compounds.

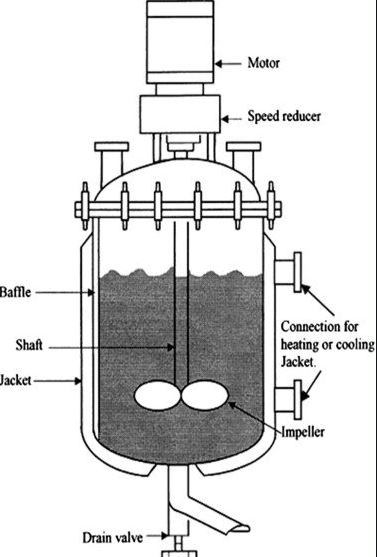

What are the Main Components of the Stirred Tank?

In order to have a clear understanding of how the攪拌容器係統works, you have to know the main components.

以下是您應該了解的攪拌罐的主要組件。

Stirred tank

· 坦克

This is the outer part of the stirred tank that you will use to hold different capacities of compounds to mix.

您可以選擇不同品種和坦克的能力,用於不同化合物的混合過程。

· Mixer Drive

這是攪拌罐的機械部分,其將有助於混合不同化合物的混合器的旋轉。

您可以舒適地控製混合器驅動器的速度,這反過來將控製攪拌係統的速度。

·混合器或攪拌葉片或攪拌器

You will use the mixer to assists in the process of stirring or mixing the different types of compounds within the stirrer tank.

機或攪拌機的運動和速度很快就會回來的l depend on the driving force that comes from the mixer drive.

·頂部頭部噴嘴

You will depend on the top head nozzles to help in the release of pressure that might accumulate within the stirred tank.

It will get rid of the pressure in significant quantities in order to avoid the occurrence of an explosion.

·大氣道

You will open the larger manway to allow the addition of different biological and chemical compounds into the stirrer tank.

It comes complete with a sight glass which allows you to view the whole mixing process in the stirrer tank.

· Superior Fin Baffle

You will depend on the superior fin baffle for mixing purposes as well as temperature sensing during the mixing process.

It is extra-long in order to reach the deepest parts of the stirrer tank to assess temperature of the smallest batches.

· 控製麵板

You will use the control panel to configure, program, and monitor the whole mixing process.

It comes complete with a touch screen and remote control technology that allows you operate it remotely.

· Outlet

This is the part of the stirrer tank that you will use to release the complete compound mixtures from the stirrer tanks.

隻要所有化合物都實現停留時間,您將從係統中釋放不同的化合物。

·支持係統

支撐係統包括攪拌槽的不同部件,例如攪拌槽腿,內部和外夾克。

You will note that the support systems are strong enough to withstand seismic and wind conditions as well as temperature insulation.

攪拌罐的工作原理是什麼?

攪拌的棕褐色通常在穩定的狀態下操作,在那裏它將所有通過的試劑混合在一起。

Here is a step-by-step process that you can follow to properly understand the working principle of the stirred tank.

· Preparation of Ingredients

您將通過準備您想要混合的所有成分來開始整個過程攪拌反應器.

成分的製備包括,按照將它們加入攪拌罐的順序排列。

除此之外,還必須通過正確設置機器或攪拌器罐。

您將使用控製麵板編程並配置攪拌罐,然後讓它熱身。

· Addition of the Ingredients

You will proceed with the addition of the ingredients into the stirred tank through the inlet of the tank.

Remember that it is important to quantify the amount of ingredients that you will be adding into the stirred tank.

You must also add these ingredients in a particular order so as to avoid misfortunate occurrences.

· Mixing Process

當您在攪拌罐中添加更多成分時,攪拌器將采用攪拌方法進行。

It will stir all the ingredients accordingly at a speed which you will dictate from the control panel.

During the mixing process the sensors and monitors within the tanks will communicate the temperature ratings.

You can also control the temperature and pressure within the stirrer tank by releasing the pressure through top head nozzles.

該過程將繼續,直到獲得均勻的混合物,直到停留時間結束。

Finally, the machine will release the mixture automatically from the tank through the outlet.

使用了坦克的好處是什麼?

Well, there are numerous benefits that you will derive from the use of the stirrer tank.

Here are some of the advantages of using the stirrer tank in your varying applications.

· Proper Temperature Control

You can easily control and maintain the temperature of the whole reaction system.

It has a control panel where you will control the overall temperatures and insulating jackets for heat insulation.

· Cheaper to Manufacture

與其他類型的罐或反應器相比,您將在攪拌器罐的結構上花費少。

盡管建築成本廉價,但使用的材料具有非常高的質量,並且很容易獲得。

· Large Heat Capacity

You have the freedom of controlling the heat within the stirred tank due to the large heat capacities.

除此之外,大的熱容能能夠容納產生大量熱量的反應。

·輕鬆清潔和維護

由於易於訪問內部,您可以輕鬆清潔和維護攪拌器罐,以最小的搭便車或問題。

您所要做的就是打開攪拌罐的上部並進行清潔和維護功能。

· Low Operation Cost

由於它快速工作,因此您還將在攪拌器罐的運行中花費較少,並且使用很少的能量。

You will save on the cost of paying power bills and will also avoid expenditure on excess wastage of raw materials.

What are the Disadvantages of Using the Stirred Tanks?

Despite the numerous benefits that you will enjoy, there are particular limitations to the stirred tanks.

Here are some of the limitations that you might experience while using the stirred tanks.

·反應物的小轉化

您將注意到攪拌的罐體將反應物轉化為每體積反應物的最終產物。

There are other flow reactors that have a greater conversion of the reactants to final product per volume of reactants.

· Development of Dead Zones

在混合過程中,攪拌罐內有可能的死區顯影。

Dead zones are the areas within the reactor where the stirred tank cannot access the reactants for mixing purposes.

·反應物旁路

You may also realize that the reactants flow through the stirred tank without proper mixing or reaction.

This will happen in a situation where the outlet is in the wrong position thus prompting release of reactants.

How Many Types of Stirred Reactors Do You Supply?

攪拌罐反應器

使用攪拌罐的一個好處是它的靈活性和多功能性,具有多種類型的可用性。

根據攪拌罐的應用要求,您將在不同類型的反應堆中進行選擇。

Here are the different types of stirred tanks that you can choose depending on the application requirements.

- 微生物攪拌罐或發酵罐

- 細胞結構攪拌罐或生物反應器

- 一次性或單一使用生物反應器

- 用於特殊應用的生物反應器

What is the Difference Between Microbial Stirred Tanks and Cell Culture Stirred Tanks?

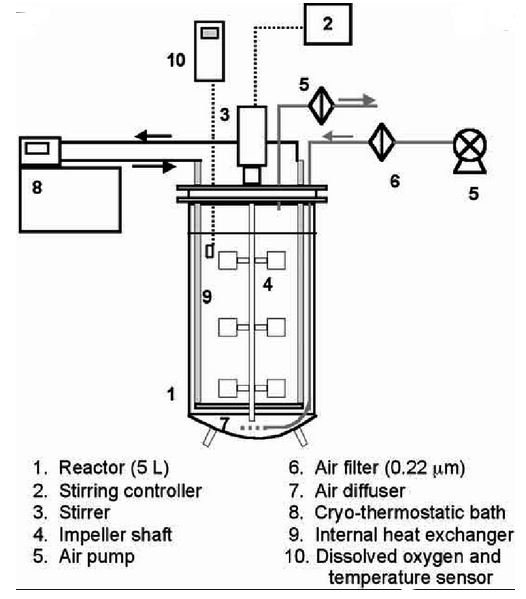

The main difference between the microbial stirred tanks and cell culture stirred tanks is operation mode.

Here is a direct comparison between the microbial stirred tanks and the cell structure stirred tanks.

Microbial Stirred Systems

您將使用微生物攪拌罐高剪切,快速混合以及適當的氧氣轉移。

Microbial stirred tanks have various characteristics that help in the mixing of the different microbial compounds.

您可以使用微生物攪拌罐混合的一些微生物化合物是細菌,真菌和其他酵母。

The typical characteristics of the microbial stirred tanks or bioreactors include:

- 高度或直徑縱橫比

- Flat bladed, multiple turbine impellors

- 高燃氣轉移率

- Antifoam systems with antifoam sensors.

Cell Structure Stirred Tanks

You will use the cell structure stirred tanks to help in the reduction of system contamination over a particular period.

它使用溫和的混合技術,同時使用氣體混合進行適當的氧氣傳輸經驗。

您應該在電池結構攪拌罐中尋找的典型特性包括:

- Low speed and gentle mixing process

- 辮子海洋葉輪係統

- 使用二氧化碳代替酸以控製pH。

- Use of Nitrogen and Oxygen in the low-flow gas mixtures control of PO2.

單次使用攪拌罐與特殊應用的生物反應器進行比較嗎?

除了兩種類型的攪拌罐外,還有其他類型的攪拌反應器,您可以使用。

Here is a comparison between the single use stirred tanks and special use stirred tanks.

單用攪拌罐

You will use this type of stirred reactor in a situation where validation and speed of the process is required.

它將幫助在拯救的準備以及cleaning time thus increasing the overall speed of reaction.

但是,您必須在每個文化過程之後替換它們以獲得驗證的目的。

Here are the main characteristics of the single use stirrer tanks.

- Pre-sterilized to save on the cleaning time

- Fewer options for customization

- 更少的傳感器選項

- Extractable or leachable considerations

攪拌罐for Special Applications

您將攪拌罐用於特殊應用,以混合落在特殊類別內的反應物。

將不同類型的物質如真菌,藻類和生長在固體上的厭氧細菌的混合是合適的。

In this case, you will have to look at different adaptation variations such as geometry, design, as well as mixing techniques.

您可以根據尺寸對攪拌罐進行分類嗎?

絕對,您還可以根據不同的罐尺寸對不同類型的攪拌罐進行分類。

在這裏,您將每批攪拌罐式反應器看看您需要的培養物量。

In this case, you can choose among the three types which include:

- Small-scale or Parallel Bioreactors (For applications under 1 liter)

- 台級生物反應器(適用於1到10升之間的應用)

- Pilot Scale Bioreactors (for applications more than 10 liters)

如何通過飼養策略將攪拌的反應器分類?

You can also categorize the stirred tanks according to the mode of addition and removal of the reactants.

Here are the three main categories of stirred reactors according to the feeding strategies.

不鏽鋼攪拌罐

· Batch Stirred Tanks

In this case, you will not include any liquid feed within the stirrer tank and eliminate none as well.

It is the most ancient form of categorization where the larger the tank reactors the greater the results.

· Fed-Batch Stirred Tank

在這裏,您將選擇饋送策略,例如步驟,線性,劑量或指數,您將用於添加更多基板。

At the end of the reaction, you will not remove any form of culture especially in high density cultures.

You may also choose to use multiple feeds depending on the mode of application as it helps in triggering specific genes.

·連續文化攪拌罐

Here, you will add and remove liquid substrates at specific rates by keeping cell density or substrate concentration constant.

You will perform the continuous culture for a longer period which usually lasts for days or even months.

It is the most productive type but it will take quite a lot of time to create a perfect set up.

收購攪拌罐的價格範圍是多少?

好吧,由於攪拌罐的不同尺寸,類型和類別,您應該期待廣泛的價格範圍。

攪拌器罐的質量越好,您將支付的金額越高。

In this case, you will look at quality in terms of the level of technology in the stirred tanks and durability.

除此之外,您正在購買的攪拌罐更大,您將支付的金額越高。

一般來說,攪拌器罐將花費5,000到60,000美元之間的購買。

如何控製攪拌罐的操作溫度?

您可以通過查看相當多的因素來控製攪拌罐的操作溫度。

以下是您可以使用的部分選擇,以正確控製攪拌罐的溫度。

· Checking the Quality of Cooling Water

You should check on the quality of cooling water that cools the stirrer tank on a regular basis.

In this case, you will look at the type of water in terms of hardness as well as organic or bio-count contents.

·控製反應參數

You can also control the parameters of reaction from the control panel where you will dictate the temperature ranges.

The machine has the capability of controlling the temperatures of the reactions with the help of the sensors.

·穩定反應速率

You should also stabilize the rate of reaction within the stirrer tanks by ensuring that the working parameters are perfect.

This will eliminate unstable reactions within the stirrer tank and minimize the amount of heat the stirrer tank produces.

Which Specifications Do You Look at When Choosing a Stirred Tanks?

在做出決定之前,您還必須有計劃在攪拌箱中所需的東西。

Here are some of the specifications that you can look into when choosing the stirred tanks.

· Dimensions of the Tank

You will look at the dimensions of the stirred tank in terms of size and capacity that the tank can handle perfectly.

攪拌罐可以處理小於一升反應物,而其他罐可以處理超過10升。

·攪拌罐的類型

各種應用中有許多類型的攪拌罐。

You should choose a stirred tank according to the industrial application requirements.

·材料類型

在這裏,您將在功能和耐用性方麵看看諸如材料類型的特定因素。

您應該選擇最佳類型的材料,這些材料將很長一段時間為目的服務。

這是製造攪拌罐的最佳材料?

You can use different types of materials in the manufacturing process of the stirred tanks.

Some of the materials that you can use to make the stirred tank include:

- 不鏽鋼材料

- 碳鋼材料

- Glass Materials

These materials are highly durable and also has very high mechanical and tensile strength.

Apart from that, they have very good heat conducting capabilities while withstanding the effects of high temperatures.

你如何清潔和維護攪拌罐?

Well, cleaning and maintaining the stirred tanks is a very simple process due to the design of the stirrer tanks.

攪拌罐讓您輕鬆地訪問內部部件,從而使整個清潔體驗簡單。

Here are some of the things you will do when cleaning the stirred tanks.

首先,您將不得不停止攪拌罐的所有操作,讓它冷卻。

After that, you will open up the upper part of the stirred tanks to gain proper access to the internal parts.

You can refer to the daily inspection records to identify the parts of the machine that require maintenance.

After that, you can begin the cleaning process by soaking and scrubbing off the stubborn stains from the equipment.

As soon as you complete that, you will make sure that you get rid of all the residues within the pipe delivery systems.

Remember to replace the broken parts and repair the lose parts in case the damage is not extensive.

Finally, you will replace the parts of the stirred tank slowly in readiness for testing and continuous operations.

How Do You Increase the Efficiency of the Stirred Tank?

You can increase the efficiency of the stirred tanks by performing the following functions.

· Proper Record Keeping

您應該花每日記錄攪拌器罐的操作,這將有助於識別故障。

With this information, you will be able to adjust the faults on the stirrer tank accordingly to increase efficiency.

·機器的適當配置

You must also use the control panel indiscriminately to optimize the functions of the stirred tanks.

Setting the configurations to work at maximum efficiency will help in improving the overall working output.

·定期清潔

您還必須定期清潔機器以擺脫可能阻礙性能的雜質。

· Replacement of Parts

一旦它們破碎或磨損,您還必須定期更換攪拌器罐的部件。

What is the Difference Between the Stirred Tanks and the Plug Flow Reactor?

Well, you can use the stirred tank reactors and plug flow reactors to mix different reactants.

攪拌罐式反應器使用罐和攪拌器來幫助混合不同的流體和固體試劑。

您將通過入口側介紹試劑,並使混合物通過出口側離開。

另一方麵,插頭流量反應器不使用罐或攪拌器,而是用於混合目的的整個管。

In this case, different fluid reagents will flow through the tube and collide with others.

It will result into the release of a homogenous mixture at the other end of the tube.

How Does the Batch Reactor Compare to the Stirred Tanks?

批量反應堆

您還可以使用批量反應器並在整個試劑混合過程中攪拌罐。

批量反應器是最簡單的混音器形式,可以在設定時間段內混合不同的試劑。

On the other hand, you will also use the stirred tanks to mix different reagents using a tank and stirrer.

在這兩種情況下,必須控製混合試劑的溫度和壓力。

Apart from that, the resident time distribution is also a very important factor to consider.

化學反應器是攪拌器罐嗎?

Yes, stirrer tanks are special types of化學反應器that you can use in the mixing of different types of reagents.

在短暫的情況下,攪拌反應器來自各種形狀和設計,具有不同的性能。

You cancontact FilSon Filtersnow for all your stirred tank needs.